Our mission

More than 40% of the beautiful crops that grow on our fields are wasted and do not end up on a plate. This is not acceptable in a world with a growing population and so many mouths to feed. We have to stop the ridiculous waste flow of fresh food.

We at Ultrasonic Mist want to contribute to the reduction of this waste flow and at the same time increase the supplier’s profit.

ULTRASONIC MIST Presentation Video

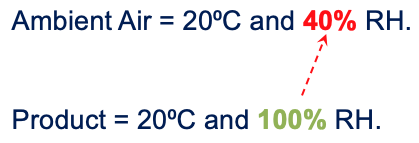

WHY DRY MISTING?

Food waste reduction

Cost savings

Weight retention

Extends storage and shelve life

Water savings

Energy savings

Products quality improvement

Less plastic packaging required

Improved nutrients and taste

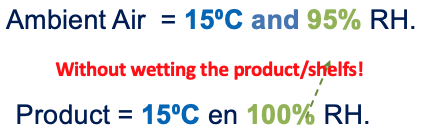

No wetness on product

In store theatre (dry mist draws customer attention)

40 - 60% Waste reduction

About

Ultrasonic

Ultrasonic Mist is the sole distributor for South Africa and neighboring countries approved by Contronics. Contronics have been the leading supplier throughout European countries, in the ultrasonic mist field, for over 40 years. They have received several awards for this technology and service.

Contact UsUltrasonic VS Misting

Ultrasonic technology

Dry Misting

1-2µM aerosols – No visible droplets on product

Produce absorb small micron sized water

particles much easier enhancing re-hydration

More ideal for indoor RH control like display

shelves, cold room or open refrigerated displays

100% product coverage

Misting technology

Wet Misting

25µM droplets - Visible droplets on product

More ideal for outdoor cooling and RH control

e.g Greenhouses covered with netting

Only covers the top layer of product when used

indoors

Hydrated

Dehydration

Get in Touch with US

We are always happy to hear from you.

Visit my Contact page now to send us a message.

Get in touchYour application

From postharvest through storage and transportation to the supermarkets shelves.

Fruit & Vegetables

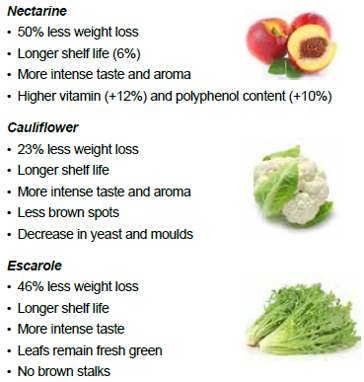

Fresh produce tends to deteriorate quickly: low humidity causes it to lose a lot of moisture.

Dry Misting technology developed by Contronics will help you counteract this effect. As the mist evaporates, the humidity rises and the temperature drops naturally.

Your produce will retain its freshness, colour and nutrients for a significantly longer time!

Besides an increase in quality and weight, our Dry Misting technology offers additional advantages, such as:

Less spoilage so more to sell

Mist eliminates the need for packaging

Our systems contribute to sustainability by reducing waste, energy consumption and CO2

Meat

Consumers will judge meat cuts based on their visual appearance. That is why it is essential for your cuts to look fresh and of high quality at all times. One obstacle to achieving this is the need for refrigeration: it draws moisture from your products, causing meat cuts to change colour and salads to form crusts — not to mention the weight loss. Dry Misting technology developed by Contronics will help you counteract this effect.

Our systems make the finest mist from the purest water, which will surround your meat cuts like a blanket. As it evaporates, the humidity rises and the temperature naturally drops. Your cuts lose no more moisture and retain their fresh appearance, their colour and their weight, without getting wet.

In addition to longer shelf life and improved freshness, our Dry Misting technology offers additional advantages, such as:

Reduce waste by no longer having to cut off visually unappealing meat

Better weight retention

The natural cooling effect helps you save on energy

Cold storage

The condensers in refrigeration systems draw moisture from the air and, as a result, from the produce in the cold store. The greater the temperature difference, the more water is drawn out. Dry Misting technology developed by Contronics will help you counteract this effect.

Other

Fish

Consumers judge fish based on its visual appearance. That is why it is essential for your products to look fresh and of high quality at all times. One obstacle to achieving this is the need for refrigeration which draws moisture from your products, causing the fish fillets to lose weight and be often hidden under a layer of ice. Additionally, colours may shift and oxidation may occur so that the fish appears less fresh.

Dry Misting technology developed by Contronics will help you counteract this effect.

Our systems make the finest mist from the purest water, which will surround your fish like a blanket. As it evaporates, the humidity around your products rises. Your fish loses no more moisture and retains its colour and weight, without getting wet.

In addition to longer shelf life and improved freshness, our Dry Misting technology offers additional advantages, such as:

Reduced waste by no longer having to cut off unappealing parts of the fish;

Better weight retention;

No condensation on the fish, making Dry Misting very suitable for fillets;

The natural cooling effect helps you save on energy;

Scares off flying insects and cuts back on unpleasant smells;

Bread

Humidity is one of the most decisive factors in the baking process directly affecting the quality of the bread. Contronics produces fine mist (Dry Misting), which allows you to further improve the quality of your product, optimise your baking process and save on energy all at once.

Prompted by the European Commission’s NanoBAK research project (www.nanobak2.eu), Contronics cooperated with several prominent associates from the baking industry to develop a unique form of technology to apply cold mist during the proofing and cooling process in bakeries.

Cheese

When maturing (mainly) soft cheeses, high humidity is required. Cheese producers use controlled humidity to accurately manage the ripening process. The desired relative humidity for this process can be as high as 95%. Our Dry Misting technology is able to provide these high levels of relative humidity without causing wetness on the product and in the chamber.

Wine

Throughout the aging process, a large measure of the valuable wine evaporates from the wooden barrel. It can lead to significant losses in yield. We can help reduce this evaporation loss by 70% by applying Dry Misting technology in wine cellars without causing wetness and mould.

Tobacco

Cigars are produced in regions where the air is relatively humid. To maintain their rich quality, cigars should be kept in a humid climate during storage and in humidors. Our Dry Misting technology can provide high relative humidity without wetting the cigars, enabling optimal circumstances to maintain the highest cigar quality.

Flowers

Cut Flowers: Apart from the right temperature, some freshly cut flowers favour high relative humidity. The condensers in refrigeration systems draw moisture from the air and, as a result, from the fresh flowers. Thanks to Dry Misting technology, fresh flowers maintain their moisture level and freshness over a longer period of time.

Flower Bulbs: Flower bulbs, need to be humidified to soften their skin so that they can be peeled efficiently. Our Dry Misting is proven to be the best solution for this as it minimises mould growth and enables quicker drying after peeling, compared to other technologies.

Transport

The longer the distribution route, the bigger the challenge to offer freshness to the consumer. To help you with this, we have developed a solution to apply Dry Misting technology during transportation.

Disinfection

Besides misting with only the purest water, Dry Misting technology can also be combined with the natural antimicrobials (bioflavonoids) and ECAS (electrolyzed water). By these methods the aerosols get disinfecting properties. It is 100% non-toxic and non-corrosive. The combined effect results in the further extension of the shelf life of the fresh products as the antimicrobials limit the growth of micro organisms on the product.

Animation video indicating the advantages of Ultrasonic Mist

Process Flow

Farms and Cold Storage (aka post harvest)

Transport/Shipping Local and Export

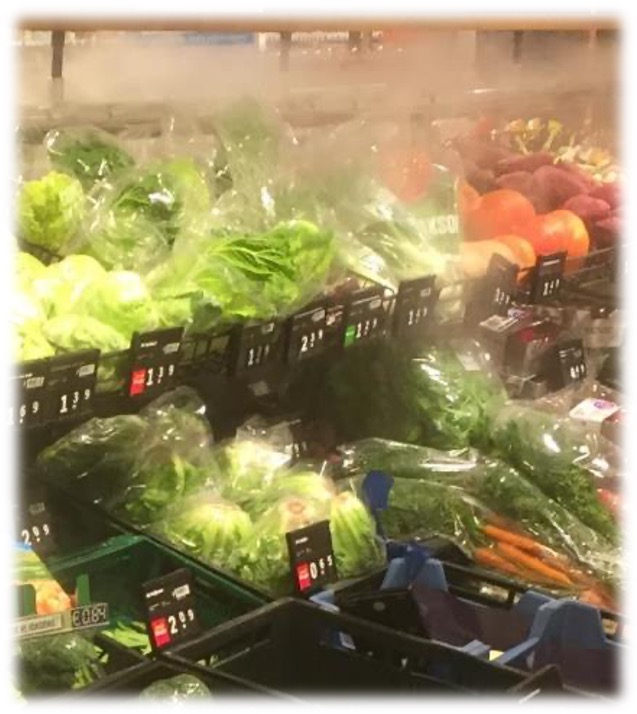

Retail Store Shelves and Cold Storage

Dry mist is visible on top of the shelve but

measurements prove an even RH throughout

Advantages for Refrigerated Display

Product

Longer shelf life

Retains its weight

Customer

Fresher appearance

In store theatre

No wetness

Planet

Less waste (CO² / water /nutrients)

Energy saving (eg. 5.4kWh / 3.65m open display fridge)

Plastic Packaging

Dry mist offers the opportunity to have less plastic on the shelfs.

The effect is optimal on products without plastic packaging.

Most packaging is perforated, this allows the high humid air to reach the product, so there is still an effect!

Even completely sealed products still benefit from the cooling effect. (keeps product cooler)

Hygiene guaranteed

Water filtered to the purest form (incl. continuous safeguard)

Ensuring no impurities like

- no calcium

- no bacteria

- no viruses

- no nutrients for bacteria

A built-in sensor continuously checks the water quality, with any anomalies the system is switched off automatically

Eliminates airborne bacteria

A built-in ozone generator automatically kills bacteria every 24hrs that might be in the ambient air.

Ozone is generated from oxygen, after a short period it changes back into oxygen without leaving residue

No still standing water

Water in the system is rinsed every hour

When the system is shut down the reservoir is automatically drained

Stainless steel and food grade PVC

Both stainless steel and food grade PVC reduces the adhesion of bacteria or mould growth.

Annual Maintenance and Cleaning

Of outlets, filtration, ultrasonic machine and parts

Horizon 2020 – Fresh Demo Results

Contact Us

Use the form below to get in touch. If you have any questions or need help with anything, we are always happy to hear from you.

Contact Details

Head Office: Kempton Park, Gauteng

Tel: +27 79 504 2455

Email: luan@ultrasonicmist.co.za

Servicing South Africa and neighboring countries

Frequently Asked Questions

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim.

Contact Us

TEL:+27 79 504 2455

EMAIL: luan@ultrasonicmist.co.za

WEB: ultrasonicmist.co.za

ADDRESS: 10 Peperboom ave

Kempton park

Gauteng

Follow Us

Powered by Genlead